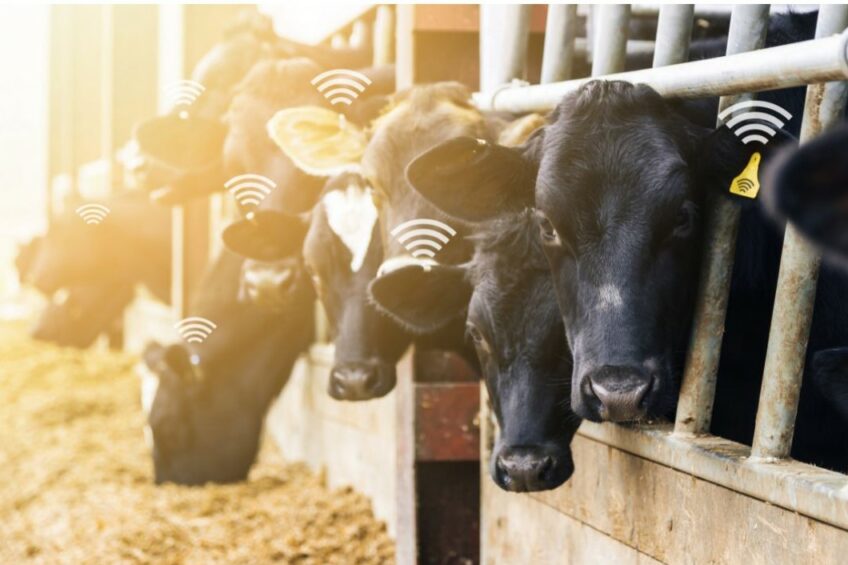

The Biometric Surveillance Era

The modern dairy cow moves through her day enveloped in a web of sensors that would astonish farmers of even a decade ago. Smart ear tags equipped with accelerometers track her grazing intensity by measuring the angle and frequency of head movements during feeding. Concurrently, rumination collars wrapped gently around her neck detect the distinctive jaw motions of cud-chewing through piezoelectric sensors that convert physical pressure into electrical signals. These devices don't merely record activity—they interpret behavior patterns with startling precision. At the University of Missouri's research dairy, scientists have documented how these systems detect the onset of estrus through micro-changes in activity that escape human observation. When a cow enters her fertile window, her movement patterns increase by 300-500% in specific frequencies, triggering instant alerts to herd managers' smartphones. This technological intimacy has increased conception rates by 25% while reducing semen and labor costs significantly across progressive operations.

Hoof-Mounted Health Monitors

Beyond neck and ear, even bovine feet now contribute diagnostic data. Step-counting leg bands equipped with triaxial accelerometers differentiate between normal walking, restless pacing indicative of discomfort, and the distinctive weight-shifting patterns associated with developing lameness. Research published in the Journal of Dairy Science demonstrated these devices identify hoof lesions 48 hours before visible symptoms emerge. The economic implications are profound: early treatment of foot conditions costs approximately $42 per case versus $278 for advanced interventions, representing a potential industry-wide savings of $1.2 billion annually in veterinary expenses alone.

The Manure Metamorphosis

What was once considered a problematic waste stream has transformed into a revenue-generating asset through technological reinvention. Anaerobic digesters now dominate large-scale dairy operations, using controlled bacterial decomposition to convert manure into methane-rich biogas. At the Riverview LLP complex in Minnesota, 15,000 cows produce sufficient biogas to generate 5 megawatts of continuous electricity—enough to power 3,500 homes while reducing the operation's carbon footprint by 60%. The residual digestate undergoes mechanical separation where screw presses divide liquids from solids. The liquids become precision fertilizer, injected directly into cropland through GPS-guided systems that match application rates to soil nutrient maps. The solids transform into pathogen-free bedding material, reducing reliance on costly sand or sawdust. This closed-loop system demonstrates how technology transforms environmental liabilities into economic assets.

Methane Monetization

The frontier of manure technology now extends beyond electricity generation to renewable natural gas (RNG) production. After biogas purification through membrane filtration systems that remove CO₂ and hydrogen sulfide, the resulting methane meets pipeline specifications. California's Low Carbon Fuel Standard program creates a lucrative market, with credits currently trading at $200 per ton of CO₂ equivalent reduction. For a 2,000-cow dairy, this translates to $600,000 in annual revenue—a figure that fundamentally alters manure management economics. Emerging technologies like hydrothermal carbonization now promise to extract even greater value by converting manure into biochar soil amendments and advanced biochemical precursors.

Predictive Health Analytics

The integration of multiple data streams creates unprecedented predictive capabilities for bovine health. Systems like Connecterra's Ida employ machine learning algorithms that correlate rumination minutes, resting bouts, milk conductivity, and feeding behavior to identify health issues before clinical signs manifest. At the DeLaval Innovation Center, researchers documented how subtle deviations in rumination patterns—a 14% decrease over 36 hours—correlate with subclinical ketosis with 91% accuracy. When such deviations occur, automated systems adjust individual rations by dispensing propylene glycol supplements through smart feed bins. Similarly, milk spectroscopy sensors now detect immune response markers associated with mastitis 24 hours before visible signs appear in the milk or udder tissue. Early intervention reduces antibiotic usage by 35% and cuts treatment costs by $444 per case according to National Mastitis Council studies.

Calving Prediction Networks

Perhaps nowhere is predictive technology more impactful than in maternity management. Vaginal implantable thermometers connected to LoRaWAN networks detect the characteristic 1.5°F temperature drop occurring 4-6 hours before calving. Simultaneously, accelerometer-based tail sensors monitor the distinctive muscle contractions of second-stage labor. Integration of these systems triggers sequential alerts: first to farm managers when calving is imminent, then to veterinary staff if labor progression stalls beyond predefined parameters. Wisconsin field trials demonstrated this technology reduces stillbirths by 15% and decreases dystocia-related veterinary emergencies by 40%, transforming what was historically agriculture's most sleep-deprived season.

Genetic Intelligence Platforms

The genomics revolution has moved far beyond simple trait selection. Modern genomic evaluation platforms now process over 100,000 genetic markers per animal, weighing production characteristics against resilience metrics. Organizations like the Council on Dairy Cattle Breeding have shifted selection indices to emphasize balanced performance: 40% production (milk, fat, protein), 30% health (mastitis resistance, fertility), 15% longevity, and 15% efficiency (feed conversion, methane output). The impact is measurable: between 2020-2025, the average productive life of Holsteins increased by 4.2 months while feed efficiency improved by 7%. CRISPR gene-editing now promises quantum leaps, with researchers at UC Davis successfully introducing a thermotolerance gene variant into dairy embryos that reduces heat stress impacts by 60% in early trials.

Robotic Milking Ecosystems

The modern milking robot functions not merely as automation but as a diagnostic health station. DeLaval's Voluntary Milking System allows cows to self-schedule milkings according to their physiological needs, increasing production by 10% through optimized milking intervals. During each session, in-line spectrophotometers analyze milk composition in real-time, measuring fat globule size, protein fractions, and somatic cell counts. When abnormalities emerge—such as elevated plasmin enzyme levels indicating subclinical infection—the system automatically segregates milk and alerts management. The latest generation robots incorporate 3D teat mapping cameras that adjust milking cup placement dynamically to accommodate udder morphology changes throughout lactation, reducing liner slips and improving teat-end health.

Precision Nutrition Systems

Feeding technology has evolved from group rations to individualized nutrition plans. Smart feed bins equipped with RFID readers identify each cow as she approaches, dispensing customized rations based on her production stage, health status, and genetic potential. At Pennsylvania State University's research farm, this approach reduced feed costs by 14% while increasing milk yield by 6% through precision amino acid balancing. Rumen boluses continuously monitor pH, temperature, and pressure, transmitting data that enables dynamic ration adjustments. When rumen pH drops below 5.8—indicating subacute acidosis—the system automatically increases effective fiber in subsequent feed deliveries.

Water Reclamation Engineering

Water stewardship now operates through sophisticated closed-loop systems. At Fair Oaks Farms in Indiana, plate coolers capture heat from freshly harvested milk (101°F) to pre-warm water for cleaning systems. This water then circulates through barn misting arrays that reduce heat stress during summer months. The runoff collects in sedimentation basins before transfer to constructed wetlands where aquatic plants filter nitrogen and phosphorus. Finally, the reclaimed water irrigates feed crops through subsurface drip systems monitored by soil moisture probes. This integrated approach reduces freshwater withdrawal by 87% while eliminating nutrient discharge—a blueprint for sustainable intensification.

Methane Mitigation Frontiers

Addressing enteric methane represents agriculture's most pressing environmental challenge. The most promising solution emerges from Asparagopsis armata seaweed cultivation. When incorporated at just 0.5% of dry matter intake, this red algae reduces methane production by 80% through bromoform compounds that inhibit methanogen archaea. Companies like Blue Ocean Barns now operate land-based photobioreactors producing this supplement at commercial scale. Complementary approaches include 3-NOP feed additives that chemically disrupt methane synthesis and selective breeding for low-methane-emitting genetics. The University of California's research indicates these technologies could reduce dairy's global warming impact by 50% within a decade.

Carbon Farming Economics

Cattle operations now actively participate in carbon markets through Regenerative Grazing Protocols. Using satellite-monitored rotational grazing systems, farmers sequester carbon in pasture soils while generating verified carbon credits. Microsoft's recent purchase of credits from Grassroots Carbon demonstrates corporate demand, with prices reaching $30 per ton. The Soil Carbon Index developed by the Soil Health Institute provides standardized measurement across diverse ecosystems, while blockchain platforms like Regrow Ag ensure transaction transparency. For many ranches, carbon credit revenue now exceeds 15% of traditional livestock income, creating powerful incentives for ecological stewardship.

Silvopasture Integration

The ancient practice of combining trees with pasture has been reimagined through precision agriculture. Modern silvopasture systems employ drone-planted hardwood saplings spaced according to satellite-derived soil maps. Between these alleys, high-density rotational grazing builds soil organic matter at rates exceeding 0.5% annually. At White Oak Pastures in Georgia, combining black walnut trees with cattle grazing sequesters 3.2 tons of CO₂ equivalent per acre annually while providing premium timber and nut revenue. Infrared canopy sensors monitor shade distribution, ensuring optimal animal comfort during heat waves.

Calf-Rearing Technology

Neonatal calf management has undergone a technological renaissance. Intelligent colostrum management systems use refractometers integrated with RFID wands to measure antibody concentration and record intake timing—critical factors in passive immunity transfer. Automated milk feeders prepare customized rations based on body weight, adjusting volume and frequency according to growth targets. When sensors detect reduced consumption—an early indicator of respiratory disease—the system automatically flags the calf for examination. Research from the University of British Columbia shows this technology reduces pre-weaning mortality by 22% while improving average daily gain by 18%.

Connected Barn Architecture

The modern dairy operates as an integrated technology ecosystem. Centralized farm management platforms ingest data from milking robots, feed systems, health monitors, and environmental sensors, applying artificial intelligence to optimize operations. At St. Jacobs Creamery in Ontario, the system automatically adjusts ventilation rates based on methane sensor readings, re-routes robotic milking schedules during heat stress alerts, and forecasts milk production based on weather predictions. This digital integration reduces labor requirements by 35% while improving decision-making accuracy across the enterprise.

The Labor Transformation

Technology is fundamentally reshaping dairy workforce dynamics. While robotic milkers reduce physical labor, they create demand for data analysis specialists who interpret system outputs. At California's Fiscalini Farms, traditional milking roles have evolved into "cow comfort technicians" who use tablet-based analytics to identify subtle behavioral changes. Simultaneously, automated feed pushers, manure collectors, and calf-feeding robots alleviate physically demanding tasks. This transition comes amid a 34% decline in agricultural labor availability since 2018, making technology adoption not merely advantageous but essential for operational continuity.

The Connectivity Challenge

Despite technological promise, significant implementation barriers persist. Rural broadband limitations prevent real-time data transmission on 65% of U.S. dairy farms according to USDA surveys. Battery constraints plague remote sensors, particularly in cold climates where lithium-ion performance declines. Perhaps most critically, data interoperability issues hinder integration across equipment brands—a problem the Agricultural Industry Electronics Foundation seeks to solve through CANbus 3.0 standardization protocols. These challenges are particularly acute for smaller operations lacking capital for comprehensive technology suites.

The Welfare Implications

Digital monitoring raises profound questions about animal agency and welfare. While sensors detect physical distress earlier, some ethicists question whether constant surveillance constitutes a new form of confinement. European regulations now mandate "sensor-free zones" in barns—spaces where cattle experience no electronic monitoring. Simultaneously, precision nutrition and health management have demonstrably improved well-being: University of Bristol studies document 40% reductions in lameness and 30% fewer metabolic disorders on technology-equipped dairies. This tension between welfare enhancement and behavioral freedom represents an ongoing philosophical debate within the industry.

The Economic Realignment

Technology adoption is driving structural changes across the dairy sector. Robotic milking systems costing $150,000-$250,000 per unit favor larger operations, accelerating industry consolidation. Simultaneously, data-as-a-service platforms create new revenue streams for equipment manufacturers. John Deere's acquisition of robotics specialist Blue River Technology exemplifies how traditional farm implement companies are transitioning into agricultural technology providers. For surviving farms, the productivity gains are substantial: the average technology-adopting dairy achieves 28% higher net income per hundredweight than conventional counterparts according to Cornell University analyses.

The Horizon: 2030 and Beyond

Emerging technologies promise continued transformation. Nutrient-sensing ear tags under development at MIT detect blood metabolite levels non-invasively, enabling real-time nutritional adjustments. Swarm robotics prototypes demonstrate autonomous hoof-trimming capabilities using computer vision. Most revolutionary are rumen microbiome modulators—probiotic consortia designed to optimize feed efficiency while suppressing methane. As Dr. Jennifer Van Os of UW-Madison observes: "We're moving beyond monitoring to active biological engineering. The dairy farm of 2030 will resemble a biotechnology facility more than a traditional barn."

The Ethical Imperative

This technological revolution carries profound responsibilities. As cattle become increasingly quantified and optimized, producers must balance efficiency with ethical stewardship. The industry's social license increasingly depends on demonstrating care beyond productivity metrics. Perhaps the ultimate challenge lies not in developing new technologies, but in ensuring they serve both bovine well-being and ecological regeneration—creating a dairy sector that nourishes both people and planet through intelligent innovation.

This article synthesizes research from the Journal of Dairy Science, University of Wisconsin-Madison Dairy Innovation Hub, California Dairy Research Foundation, and the American Society of Agricultural and Biological Engineers.